An armored cable is arguably one of the most common types of electrical cables. This cable type is famous for its protective layer, protecting its core from various adverse conditions, including extreme tension. The cable comes in handy across a wide plethora of applications comprising underground wiring and mains electricity supply. Unfortunately, most of us are unaware that there several armored cable types and often settle for the most common type.

The Steel Wire Armored (SWA) Cable is undoubtedly the most celebrated armor-clad electrical cable. However, it is not the only cable with armoring. It would be wise to seek knowledge on armored cable meaning before settling for a specific one for your intended application. Like conventional electrical wires, cables with armoring serve different purposes. Choosing the wrong armored cable variety often culminates in several adverse consequences, including repeated cable maintenance and replacement. This would be pretty costly in the long run.

When shopping for an electrical wire armored cable, you need to know certain critical pieces of information. For example, you need to be fully aware of the various classifications of wires with armoring. Acquiring such essential information is pretty challenging, especially for individuals without any electrical cable expertise. Fortunately, this free post provides five critical pieces of information that will help you avoid such unfortunate scenarios. Take your time and read through it keenly, and ensure that you grasp all the vital pieces of information.

An armored cable is an electrical cable that contains an extra layer of protection that safeguards its inner components from abrasion. Essentially speaking, this cable type is more rigid than conventional electrical cables and serves its purpose optimally. Sadly, most people face disappointments when dealing with this type of cable. Such disappointments often arise when you choose the wrong cable type. Most people assume that a steel armored cable is the only cable with armoring. Any decision based on this assumption is often the wrong one.

There are three distinct classifications of cables with armoring, namely;

a.Steel Wire Armored (SWA) Cable

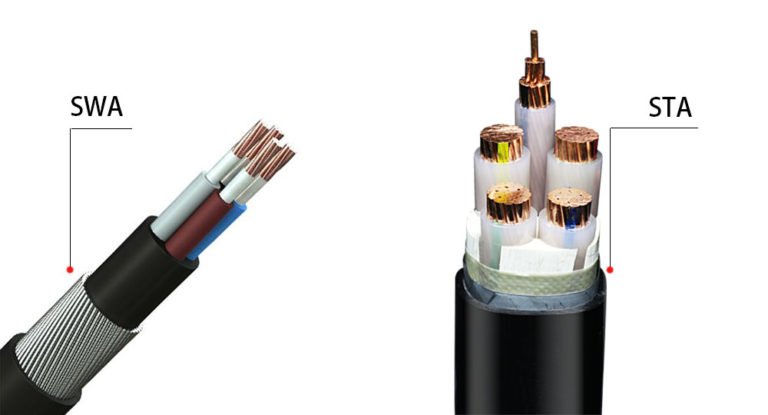

The steel wire armored (SWA) is most certainly the most renowned cable with armoring. This cable comprises a highly conductive copper conductor, XLPE or PVC inner sheath, and steel wire armor that makes up its outer sheath. Its steel armoring enables it to withstand any mechanical extremities that may damage the cable. Consequently, this armored electrical cable comes in handy when dealing with mains electric supply applications.

Armored cable manufacturers produce this cable in two distinct forms, namely low-voltage and high-voltage variations. The low voltage variant supports up to 11kV, whereas the high-voltage variant supports up to 33 kV. It would be best if you made a choice based on your intended cable. Considering that this cable is weighty and difficult to bend, it serves you better as a grounding armored cable.

b.Steel Tape Armored (STA) Cable

This armored cable is suitable for wiring applications whose current requirement does not exceed 35kV. The cable’s structure comprises steel tape armoring in its outer sheath. An STA cable is less costly than an SWA cable primarily because it is easy to manufacture.

Nonetheless, it is not wise to focus on the armored cable price over its suitability to your intended application. This cable is ideal if you want to do some wiring in a vermin and termite-infested area. It is also popular in wiring installations related to construction, underground mines, and petrochemical applications.

Before settling on a specific armored cable, you need to ensure that its minimum bending radius suits your intended application. Regardless of its classification, an armored electrical cable must not bend beneath the minimum bending radius indicated by its manufacturer. This minimum bending radius is often shown on the cable’s outer sheath.

c.Aluminum Armored Cable

The aluminum armored cable is not popular because it is only applicable for single-core wires. Aluminium armoring is ideal for single-core applications primarily because of its non-magnetic properties. Any attempt to use steel armoring in a single-conductor cable will lead to overheating.