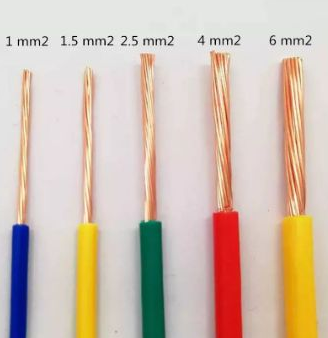

Introduction and Feature of Single cores 0.5-6 mm2 Power Cable

The power cord is used as an AC power cord and a DC DC power cord. Usually, the AC power cord is a wire that passes high-voltage AC power. The type of DC cord is basically a direct current through voltage series. Therefore, there is no AC line in safety requirements. Strict, but for safety reasons, countries still require uniform safety certification.

The structure of the power cord mainly includes an outer sheath, an inner sheath, and a conductor. Common transmission conductors include copper and aluminum metal wires.

Production Process and Related Machines

1. Conductor Bunching→

HH-B-650 High Speed Bunching machine

2. Twisted Cable Insulation→

HH-E-PLC 80+40 Extrusion Machine

1. HH-B-650 High Speed Bunching machine

Application:

It is suitable for stranding of the copper wires with more than seven strands, also suitable for electronic wires, power wires, bare copper wires, network wires etc.

Components:

|

No. |

Items |

Quantity |

|

1 |

650 Bunching machine |

1 set |

|

2 |

Pay off stand multi-core copper wire |

1 set |

Parameters:

|

Model |

Right-hand model. The operator faces its front and the wires enter it from its right side |

|

Rotation speed of arched band |

Max: 1800RPM. The bow strap is a guide wheel bow strap |

|

Twisting pitch |

15-60.24mm (can be adjusted appropriately according to customer needs), manual gear change twisting pitch |

|

Stranded wire length calculation |

How many meters per minute = twisting distance *2/1000* twisting bow speed per minute |

|

Twisting direction |

Arbitrary selection of left and right twisting direction |

|

Single wire diameter |

Ø0.16mm-Ø1.0mm |

|

Stranding area |

0.4 mm2-5.5 mm2 |

2. HH-E-PLC 70 Extrusion Machine

Application:

This equipment is suitable for outer surface extrusion of wires and cables with insulation materials such as PVC/PE.

Components:

Parameters:

|

No. |

Items |

Features |

|

1 |

Inlet Wire Diameter |

1~4mm |

|

2 |

Finished Wire Diameter |

2~8 mm |

|

3 |

Cross Sectional Area |

1~6 square mm |

|

4 |

Extrusion Speed |

Max 400 m/min |

|

5 |

Extrusion Capacity |

140 kg/h |

|

6 |

Installed Capacity |

55 kva |

|

7 |

Voltage |

380KV, can be customized |

|

8 |

Weight |

4000 kg |

|

9 |

Measurement (L*W*H) |

24*3.5*3.5 m

|