1.Application

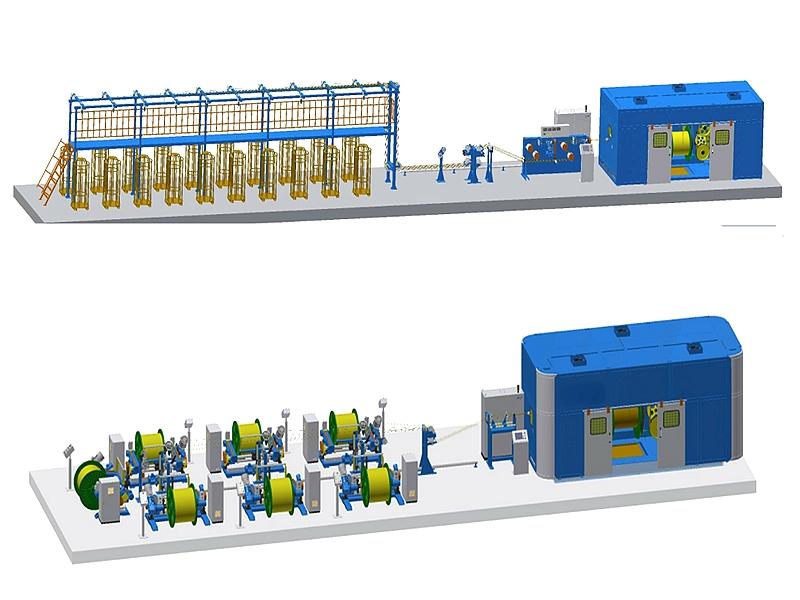

The equipment is suited for 7 strands at copper wire,aluminum wire from 16mm2 to 50 mm2 and BVR cable twist in 4 cores

2.Advantages

| 1 |

It adopts imported carbon fiber rotary double bow slices and features light weight, small centrifugal force and high rotation speed |

| 2 |

PLC controls the whole process of production line with program control of PLC stranding pitch |

| 3 |

Active type pay-off can keep constant tension of wire stringing, which avoids leakage of stranding effectively |

| 4 |

The pneumatic type jacking shaft structure is easy and convenient in operation |

| 5 |

Bearing of the machine adopts the imported brands NSK and KOYO, high strength synchronous belt transmission force with high transmission accuracy and low noise, imported gas-liquid pressurized disc braking system, up and down spool in motor-driven conveying type, standalone closed protecting cover |

| 6 |

It adopts high hardness chrome bar as a guidance during wire ranging, multi-startthread transmission force speed reduction motor drive. PLC procedure controls the pitch of cables, which can be adjusted in the working process |

| 7 |

The pre-twisting device with multi-hole inlet wire distribution plate arranges multiple wires layer by layer with concentric stranding. There is one rotating mould and two fixed moulds and squeezing moulds installed inside and outside the machine to guarantee tightness and roundness of stranded conductor |

| 8 |

The mainshaft bearing is designed with temperature control system, which will stop working and offer a reminder to add lubricating oil to make automatic protection in case of over high temperature |

3.Mechanical and electrical accessories

1.Bearings is NSK.

2.The AC and AC variable frequency Innovance or Yaskawa.

3.The AC drive adopts Yaskawa products from Japan.

4.PLC adopts Siemens products.

5.The touch screen adopts Siemens products.

6.The main low-voltage electrical components adopt domestic famous products.