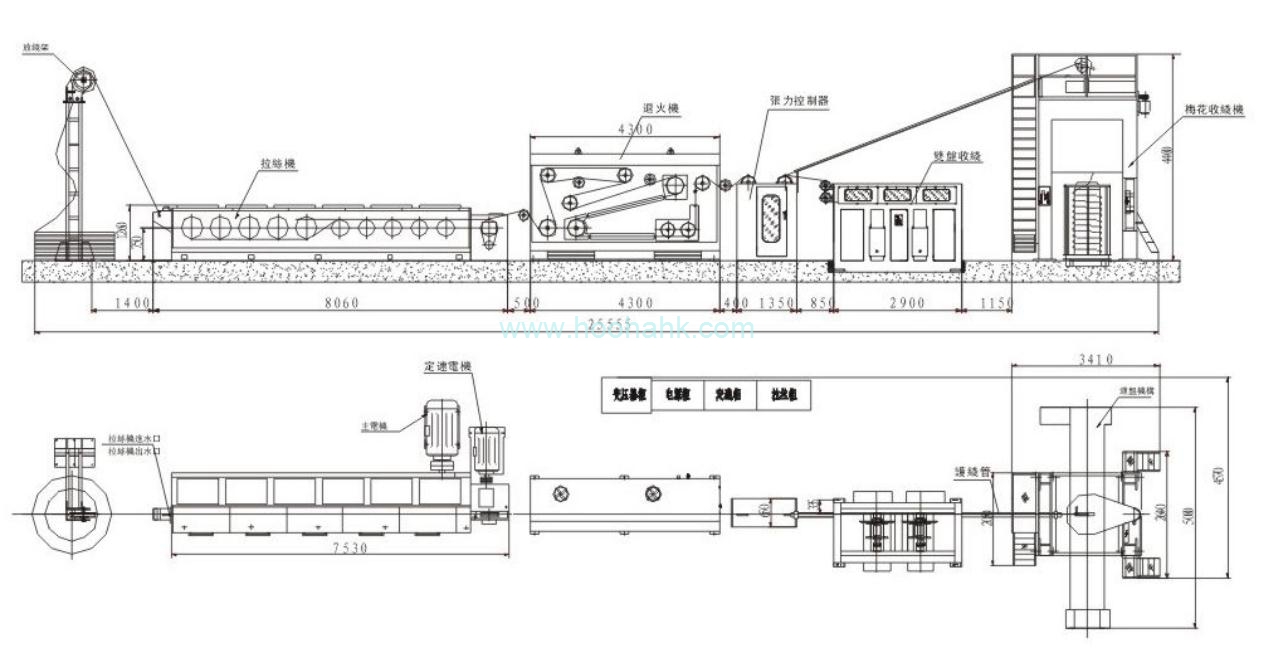

Collect fine drawn out wires and finish annealing and tinning process together on this machine. This is much more efficient and energy saving for copper wire drawing.

1. Evenly distributed temperature in the annealing furnace, energy saving.

2. Simultaneous processing of a variety of products.

3. Double-layer take-up design, reduce floor space.

|

No. |

Name |

Qty. |

|

1 |

Pay off |

1set |

|

2 |

Annealing Furnace |

1set |

|

3 |

Cooling tank |

1 set |

|

4 |

Drying box |

1set |

|

5 |

Tinning pot |

1set |

|

6 |

Capstan |

1set |

|

7 |

40 Take-up box |

1set |

|

No. |

Items |

Features |

|

1 |

Wire Size range of Annealing |

0.07~0.3 mm |

|

2 |

Number of wire processed |

40 |

|

3 |

Max. wire speed |

300M/min |

|

4 |

Pay off bobbin diameter |

300mm |

|

5 |

Pay off mold |

Curl flyer or constant tension |

|

6 |

Soften mold |

Electrical heating continuous softening |

|

7 |

Take up bobbin |

PT10-PT25 |

|

8 |

Motion power |

14KW |

|

9 |

Heating power |

35KW |

|

10 |

Traversing unit |

Casting block gear traversing |

|

11 |

Dimension(mm) L×W×H |

20000×1600×2200 |

|

12 |

Machine Net Weight |

About 4500 kg |

1.Over 20-year experienced engineer team in field of cable and wire making machines to guarantee professional solution and first-rate quality products.

2.Our professional engineer team had over 5 years experience working overseas, will provide various technologies to support our customers, including overseas on-site installation guidance, talent training, long-term technological updating services,etc.

3.Adopting famous brand parts such as Siemens, Yaskawa, Omron, Emerson to ensure reliable using of our products.

4.We check every detail of the machines and do pre-production test before delivery to eusure products quality and performance.