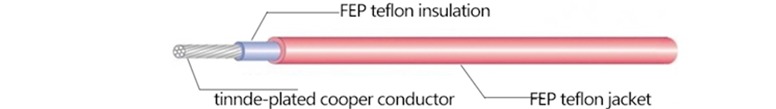

Introduction and Usage of Teflon Cable

Teflon, another name for Polytetrafluoroethylene, abbreviated PTFE. The products of this material are generally referred to as "non-stick coating";Is a synthetic polymer material using fluorine to replace all the hydrogen atoms in polyethylene.This material has the characteristics of acid, alkali, resistance to various organic solvents, almost insoluble in all solvents.At the same time, PTFE has the characteristics of high temperature resistance, its friction coefficient is very low, so it can be used for lubrication, has also become an ideal coating for the inner layer of non-stick pot and water pipe.

Features:

1. Non-sticky: Almost all substances are not bonded to the PTFE film. The very thin film also showed good ineffectiveness.

2. Heat resistance: PTFE coating film has excellent heat resistance and low temperature resistance. It can withstand high temperatures up to 300°C in a short time, and generally can be used continuously between 240°C and 260°C. It has significant thermal stability. It can work at freezing temperatures without embrittlement and does not melt at high temperatures.

3. Sliding property: PTFE coating film has a higher coefficient of friction. The friction coefficient changes when the load is sliding, but the value is only between 0.05-0.15.

4. Moisture resistance: The surface of the PTFE coating film does not stick to water and oil, and it is not easy to stick to the solution during production operations. If there is a small amount of dirt, simply wipe it off. Shorten time, save working hours and improve work efficiency.

5. Wear resistance: It has excellent wear resistance under high load. Under a certain load, it can bear the dual advantages of wear and non-interference.

6. Corrosion resistance: PTFE is hardly corroded by chemicals, and can withstand all strong acids (including aqua regia), strong oxidants, and reducing agents except molten alkali metals, fluorinated media and sodium hydroxide above 300°C And various organic solvents can protect parts from any kind of chemical corrosion.

Usage:

Polytetrafluoroethylene can be formed by pushing or extruding; it can also be made into a film and then cut into a shaft-mounted PTFE tape when used in high-temperature wires. It is used to produce high-frequency cables and directly made into water dispersion. It can be used for coating, impregnation or fiber making.

Polytetrafluoroethylene is widely used in industries such as nuclear energy, national defense, aerospace, electronics, electrical, chemical, machinery, instruments, meters, construction, textiles, metal surface treatment, pharmaceuticals, medical treatment, food, metallurgy and smelting, etc. Corrosive materials, insulating materials, anti-stick coatings, etc. make it an irreplaceable product.

Production Process and Related Machines

1. Conductor Stranding →

HH-B-500 High Speed Bunching Machine

2. Conductor FEP Insulation→

HH-E-35 Teflon Cable Extrusion Machine

Components and Parameters

1. HH-B-500 High Speed Bunching Machine

Application:

It is suitable for stranding of the copper wires with more than seven strands, also suitable for electronic wires, power wires, bare copper wires, network wires etc.

Components:

|

No. |

Items |

Quantity |

|

1 |

500 Bunching machine |

1 set |

|

2 |

Pay off stand multi-core copper wire |

1 set |

Parameters:

|

No. |

Items |

Value |

|

1 |

Single wire diameter |

Ø0.08mm-Ø0.30mm |

|

2 |

Stranding area |

0.3mm2-2.5 mm2 |

|

3 |

Stranded wire length calculation |

How many meters per minute = twisting distance *2/1000* twisting bow speed per minute |

|

4 |

Twisting pitch |

5.66 - 39.37mm |

|

5 |

Rotation speed of arched band |

Max: 2200RPM. |

|

6 |

Spindle lubrication |

Use manual grease gun to inject oil |

2. HH-E-35 Teflon Cable Extrusion Machine

Application:

This equipment is suitable for outer surface extrusion of Teflon wires and cables with insulation materials such as FEP, FPA, ETFE, PVDF.

Components:

| No. | Items | Features |

| 1 |

400-630 motorized pay-off stand |

1 set |

| 2 |

5-wheel Straightening device |

1 set |

| 3 |

Copper wire automatic sensor preheater |

1 set |

| 4 |

35 Teflon extruder |

1 set |

| 5 |

U7 non-adjustable head |

1 set |

| 6 |

Automatic drying and feeding machine |

1 set |

| 7 |

PLC Electric control box |

1 set |

| 8 |

1.5m Movable water tank with cover |

1 set |

| 9 |

Diameter tester |

1 set |

| 10 |

8m Fixed water tank |

1 set |

| 11 |

10 m Slide rail type + anode guide wheel storage rack |

1 set |

| 12 |

Dual-wheel capstan |

1 set |

| 13 |

Meter counter |

1 set |

| 14 |

High frequency spark tester |

1 set |

| 15 |

400-630 Double-head take-up machine |

1 set |

| 16 |

Spare parts |

Parameters:

|

No. |

Items |

Features |

|

1 |

Inlet Wire Diameter |

0.3~2 mm |

|

2 |

Finished Wire Diameter |

0.5~3 mm |

|

3 |

Cross Sectional Area |

0.5~2.5 square mm |

|

4 |

Extrusion Speed |

Max 150 m/min |

|

5 |

Extrusion Capacity |

50 kg/h |

|

6 |

Installed Capacity |

60 kva |

|

7 |

Voltage |

380KV, can be customized |

|

8 |

Weight |

3500 kg |

|

9 |

Measurement (L*W*H) |

23*3*3 m |

|

10 |

Workers recommendation |

3 workers |

Our stories with clients

Our stories with clients In 2012, Our Egypt customer started the first cooperation with us, and has been maintaining an in-depth cooperative relationship with HOOHA from then on. In the beginning, customers became interested in our machines on our Youtube channel and contacted us. After preliminary communication, we learned that customers do not have much experience in the production of high-temperature cables. They have spent a lot of time and energy in the research phase, but there were still many doubts remained unsolved. In order to offer customers full support, our engineers team gave them a series of guidance and suggestions for the launch of new high-temperature cable projects. In addition, they were also invited to visit our factory and our customer's production site to get a clearer understanding of the entire project start-up process. After the visit, we provided our customers with some high-temperature cables produced by our equipment for them to test. For the results of the test, the quality and standards of the cables have been evaluated to the satisfaction of the customers

PRODUCTION TRIAL BEFORE SHIPPING▲

Based on the overall understanding of HOOHA's production capacity and equipment quality, the customer quickly decided to cooperate with us. In the process of cooperation, we offered a complete upstream and downstream supply chain solution to our customers, which helped them remove a lot of confusion. Before delivery, we provided customers with quality assurance and invite them to make on-site inspections. we would not arrange shipment until the quality was guaranteed.

HOOHA pays great attention to our after-sales service. After the equipment was successfully shipped to our customer's factory, our engineers team have arranged on-site installation support and operation training to assist customers in better cable production. In addition, we have provided related technical support videos and files to fully support them. After the engineers return to China, we still provide free technical consultation and do our best to solve the technical problems encountered in their daily production.

ON-SITE INSTALLATION SERVICE▲

Since 2013, customers will bring their samples and high-temperature wire products to the China Canton Fair(Spring Fair, Autumn Fair) every year,and they have won more overseas customers at the fair. In 2016,their company developed and established 3 new subsidiaries and added new production lines.

▲FINISHED PRODUCT▲

In the development of our customers business, HOOHA have always been by our customers’ side. We are not only providing equipment support, but also helping them with production technology and full service. We are very gratified that their products have won the recognition of the market.

FAQ: