1.Description:

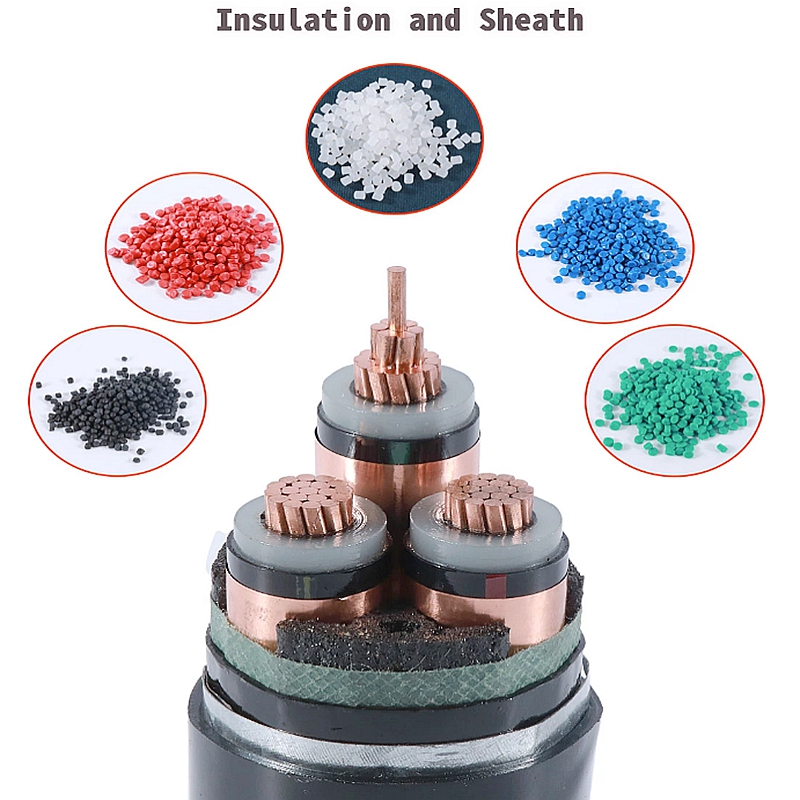

This material is a kind of crosslinkable polyethylene insulation compound. It is made of high quality PE resin, dicumyl peroxide agent and antioxidant agent by plasticizing granulation. Production process uses the closed system; Loss-in-weight Feeder which guarantees stable precision of components. It has stable physical and chemical index and good processing property.

Application: 35kV crosslinkable cable insulation; Maximum working temperature is 90ºC.

2.Technical Parameters:

|

Item |

Unit |

Test method |

Typical value |

|

|

Density@23ºC |

g/cm³ |

ASTM D792 |

0.92±0.01 |

|

|

Tensile strength |

MPa |

IEC 60811-1-1 |

22.5 |

|

|

Elongation at break |

% |

540 |

||

|

Impact embrittlement performance@-76ºC |

Failure number |

Piece |

ASTM D746 |

0/30 |

|

After aging |

Tensile strength variation |

% |

IEC 60811-1-2 |

+4 |

|

Breaking elongation variation |

% |

-4 |

||

|

Hot prolongation@200ºC, 0.2MPa, 15min |

Elongation under the load |

% |

IEC 60811-2-1 |

60 |

|

Permanent deformation |

% |

0 |

||

|

Dielectric dissipation factor@20ºC, 50HZ |

- |

IEC 60250 |

1×10-4 |

|

|

Relative dielectric constant@20ºC, 50HZ |

- |

2.25 |

||

|

Dielectric strength@20ºC |

MV/m |

IEC 60243-1 |

40 |

|

|

Volume resistivity@20ºC |

Ω·m |

IEC 60093 |

1×1015 |

|

|

Gel content |

% |

ASTM D2765 |

86 |

|

2.1.Impurity content

|

Impurities Particle Size |

Number of particles C1 |

Number of particles C2 |

|

0.12~0.25 |

6 |

10 |

|

0.26~0.50 |

1 |

2 |

|

0.51~1.00 |

0 |

0 |

|

>1.00 |

0 |

0 |

Particles number C2, unqualified.

3.Processing

Recommend to use conventional extruder (three layers co-extrusion, draw ratio is from 20:1 to 30:1) and other equipments need to be adjusted according to the circumstance.

|

Zone |

Feeding Section |

Compression Section |

Homogenization Section |

Model Section |

|

Temperature RangeºC |

90-100 |

100-110 |

105-115 |

110-120 |

Above temperature is only for reference.

4.Storage

keep at room temperature; Storage environment should be clean, dry and ventilated; Best use within six months from the date of production.

5.Product packing

500kg in each package; Inner lined with plastic sealed film bag; Corrugated carton with tray at the bottom.