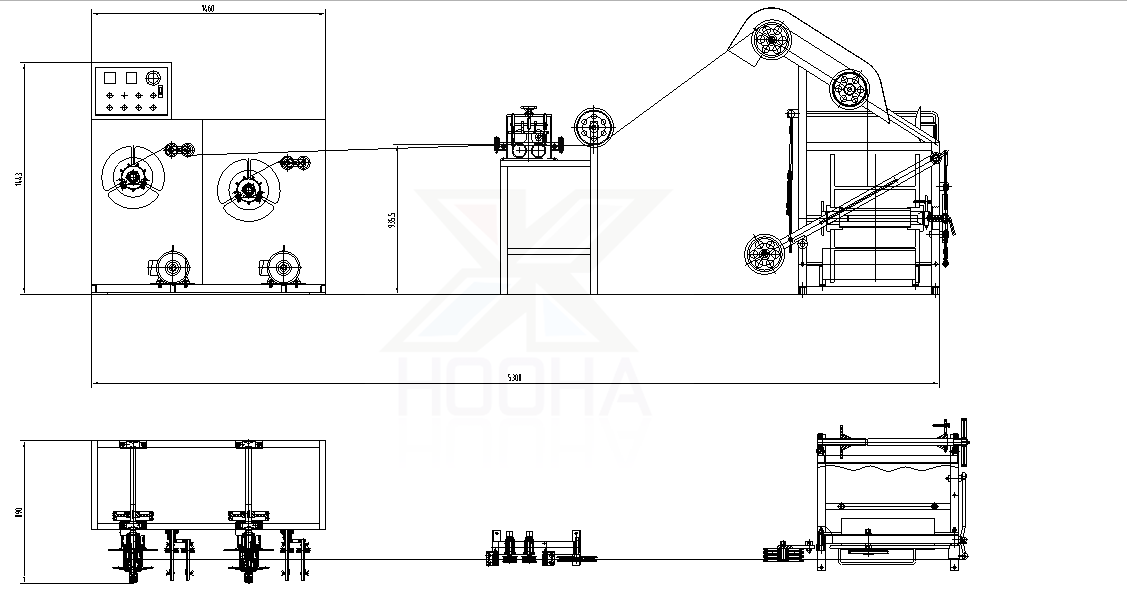

This equipment is mainly used for the coiling of 0.5-6mm2 electric wire and small section cable.The product has high production efficiency and the quality of the cable is at the advanced level of the same type of products at home and abroad.

1. Through the PLC controller, the winding speed, times and time of the CNC winding machine can be precisely adjusted, and debugging is also convenient.

2. The cables are tied tightly and neatly without affecting the wire diameter.

3. According to the input program, you can wind various specifications in the same machine.

4. Individual labor can complete the work of nearly ten people using traditional models, greatly improving efficiency and reducing business costs.

5. The automatic winding machine saves energy.

6. Workshop personnel can complete the operation after simple training, and the operation is simple

|

No. |

Items |

Quantity |

Reference Picture |

|

1 |

500-630 Tension type pay off stand |

1 Set |

|

|

2 |

High-precision Meter Counter |

1 Set |

|

|

3 |

630 High Speed Coiling Main Machine |

1 Set |

|

|

Suitable Wire Range |

0.5-6mm2 |

|

Main Machine Rotation Speed |

MAX 600 rpm |

|

Motor Power |

3 HP |

|

Wire Coil Outer Diameter |

≦ Φ320mm |

|

Wire Coil Height |

30-100mm |

|

Capacity |

700 Coils(Per 8 Hours) |

2.Our professional engineer team had over 5 years experience working overseas, will provide various technologies to support our customers, including overseas on-site installation guidance, talent training, long-term technological updating services,etc.

3.Adopting famous brand parts such as Siemens, Yaskawa, Omron, Emerson to ensure reliable using of our products.

4.We check every detail of the machines and do pre-production test before delivery to eusure products quality and performance.