闭路电视电缆的介绍和优势

介绍:

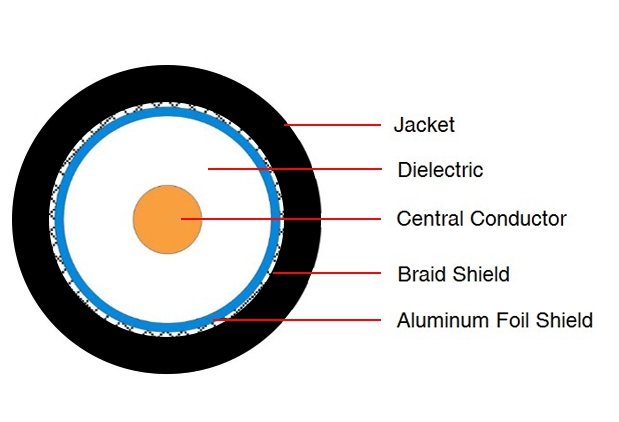

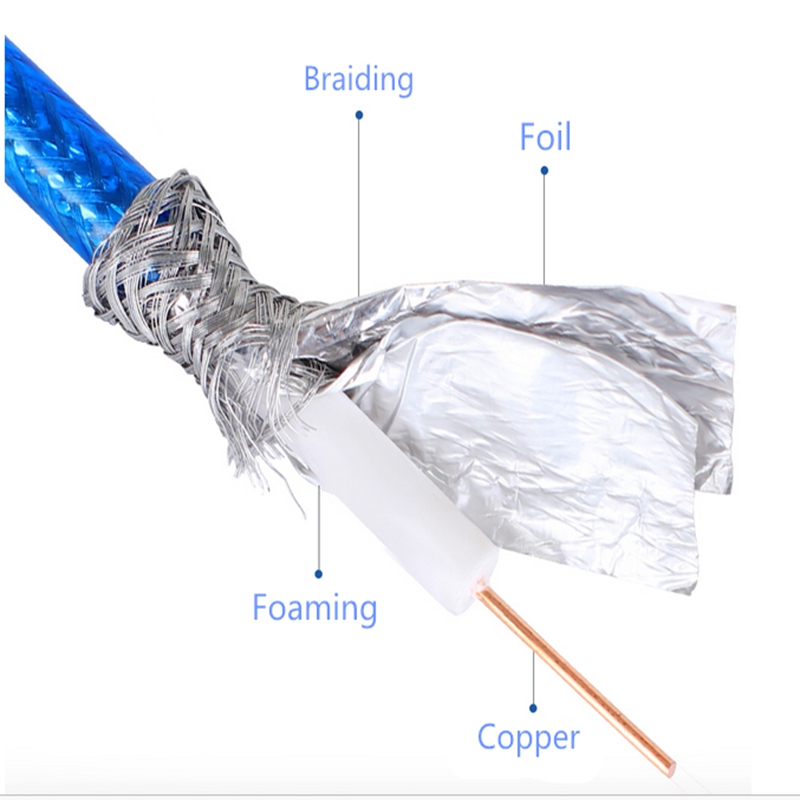

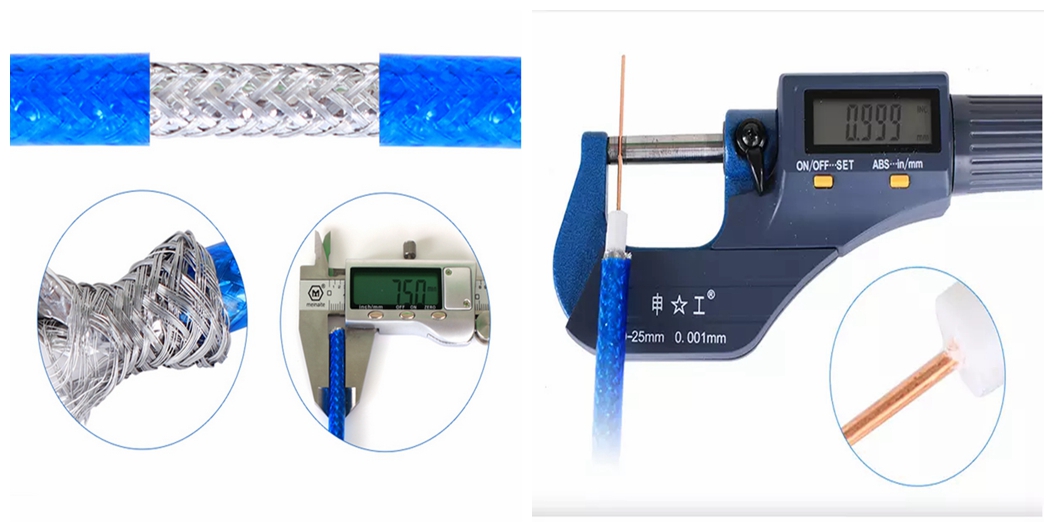

电缆的中心导体是BC。 BC代表裸铜线。 也可以是CCS。 CCS代表铜包钢。 BC具有很大的导电性。 它仅次于白银。 但是它的价格更高。 CCS相对便宜。 由于具有高频集肤效应,CCS用于在同轴电缆中传输信号。 (例如电视与VCD的连接,室外天线与CCTV等的连接)因此,与硬线相比,铜线具有更大的扩展强度。 它也可以用作在高山或河流中长期站立的架空电缆。

屏蔽分为三种类型,第一种是标准屏蔽。结构为单面APC(铝塑复合材料)胶带加上编织层。

第二个是三层屏蔽。结构为单面APC胶带加编织物加双面APC胶带。

最后,第三个是四层屏蔽。结构为单面APC胶带加编织,再加上双面APC胶带加编织。

屏蔽层可以帮助减少信号干扰。它可以防止外部条件影响传输。同样,它可以防止传输影响外部条件。

屏蔽层还用作外部导体。屏蔽层的厚度越大,密度越高,保护强度就越高。

屏蔽层的材料多种多样。它们包括铝聚合物胶带包裹,铜编织,铜胶带包裹等。迄今为止,同轴电缆已采用Al-Mg合金线的编织。因此它们可以增加强度并降低成本。铜线和覆铜铝线有点贵。因此,它的使用数量并不大。

优势:

首先,电缆具有多种应用。 它通常用于传输音频和视频信号。 您可以将其用于电视连接和计算机网络。

第二,电缆传输速度稳定。 此外,由于其绝缘,它在减少信号损耗和干扰方面也很出色。

第三,它非常耐用和灵活。 您可以使用很长时间。 而且,它很容易弯曲和运行。 因此,您可以轻松地自己安装它。

生产过程及相关机器

1. 物理发泡 →

HH-E-65+35 物理发泡双层共挤生产线

2. 编织→

HH-BR-高速 16/24 锭编织机

3. PVC 外护套 →

HH-E-PLC 70 押出机

4. 包装→

100m/Roll, 1000m/Spool

(1)成圈包装

(2)线盘包装

组件及参数

1. HH-E-65+35 Physical Foaming Two Layer Co-extrusion Machine

Application:

Two layer high pressure physical foaming production is used for high quality signal cable, data cable (skin-foam-skin) insulated core wire, adopt high pressure nitrogen inject to foaming in two layer co-extrusion production line.

Components:

|

No. |

Items |

Features |

|

1 |

400-630 active pay-off stand |

1 set |

|

2 |

Copper Wire preposition tension stand |

1 set |

|

3 |

Copper wire preheating machine |

1 set |

|

4 |

65 physical foaming host extruder |

1 set |

|

5 |

Automatic drying and feeding machine |

1 set |

|

6 |

35 inner skinning extruder |

1 set |

|

7 |

Siemens PLC electric control box |

1 set |

|

8

|

1.5m Movable water tank with cover |

1 set |

|

9 |

Diameter tester |

1 set |

|

10 |

8m Fixed water tank with cover and leak-proof |

1 set |

|

11 |

Underwater static capacitance tester |

1 set |

|

12 |

12 m Slide rail type + anode guide wheel storage rack |

1 set |

|

13 |

410mm tractor |

1 set |

|

14 |

Meter counter |

1 set |

|

15 |

High frequency spark tester |

1 set |

|

16 |

400-630 Double-head shaftless take-up stand |

1 set |

|

17 |

Accessories |

|

Parameters:

|

No. |

Items |

Features |

|

1 |

Inlet Wire Diameter |

0.8-2.0 mm |

|

2 |

Finished Wire Diameter |

3.0-8.0 mm |

|

3 |

Cross Sectional Area |

0.5-10 square mm |

|

4 |

Extrusion Speed |

Max 150 m/min |

|

5 |

Extrusion Capacity |

80 kg/h |

|

6 |

Foaming degree |

74% |

|

7 |

Centrality |

95% |

|

8 |

Installed Capacity |

75 kva |

|

9 |

Voltage |

380KV, can be customized |

|

10 |

Weight |

7800 kg |

|

11 |

Measurement (L*W*H) |

25*2.5*2.5 m |

|

12 |

Workers recommendation |

3 workers |

2. HH-BR-High Speed 16/24 Spindle Braiding Machine

Application:

It is suitable for the shielding or braiding of all kinds of high quality electric wire , computer wire etc.

Components:

|

No. |

Items |

Features |

|

1 |

16/24 Spindle Braiding Machine |

1 set |

|

2 |

Wire Combining Machine |

1 set |

Parameters:

A. 16 Spindle Braiding Machine

|

No. |

Items |

Features |

|

1 |

Braiding Direction |

Vertical |

|

2 |

Bobbin Number |

16 ( 8 is inside , 8 is outside ) |

|

3 |

Bobbin Size |

80mmx22mmx80mm |

|

4 |

Bobbin Speed |

50-150rpm |

|

5 |

Braiding Pitch |

3.2-35.5mm or 6.4-65mm |

|

6 |

Braiding Cable Diameter |

Max.14mm |

|

7 |

Production Speed |

Max.485 m/hour |

|

8 |

Braiding Wire Material |

0.1-0.2mm , Al, Mg wire , copper wire |

|

9 |

Reel Diameter |

630mm-800mm |

|

10 |

Main Motor Power |

1.1kw |

|

11 |

Product Weight |

854 Kg |

|

12 |

Dimension |

1200x1390x2350mm |

B. Wire Combining Machine

|

No. |

Items |

Features |

|

1 |

Combine wire diameter range |

0.08mm-0.4mm |

|

2 |

Speed |

0-5000 RPM |

|

3 |

Control |

Automatic stop when reel is full , or copper wire broken |

|

4 |

Motor |

0.75 KW Inverter motor , stepless speed adjustable |

3. HH-E-PLC 70 Extrusion Machine

Application:

This equipment is suitable for outer surface extrusion of wires and cables with insulation materials such as PVC/PE.

Components:

Parameters:

|

No. |

Items |

Features |

|

1 |

Inlet Wire Diameter |

1~4mm |

|

2 |

Finished Wire Diameter |

2~8 mm |

|

3 |

Cross Sectional Area |

1~6 square mm |

|

4 |

Extrusion Speed |

Max 400 m/min |

|

5 |

Extrusion Capacity |

140 kg/h |

|

6 |

Installed Capacity |

55 kva |

|

7 |

Voltage |

380KV, can be customized |

|

8 |

Weight |

4000 kg |

|

9 |

Measurement (L*W*H) |

24*3.5*3.5 m |